ATOS – Full-field 3D Scanner

ATOS is a high resolution, optical digitizer that delivers rapid and precise three-dimensional measuring data for the optimization of design processes, thereby improving industrial production processes

Quality control

Reverse Engineering

Rapid prototyping

GOM Touch Probe

The GOM Touch Probe is an add-on to the ATOS 3D Digitizer for the combination of full-field and point based 3D measurement.

Measurement difficult to access areas

Combining scanning and tactile measuring

Measurement of primitives

TRITOP – optical CMM

Photogrammetry is a technique of measuring 3D coordinates using photography as the main medium of metrology. Triangulation is method used in photogrammetry for obtaining 3D coordinates of points. The camera position in space calculation is based on the reference object. The use of factoryequiped reference objects provides the accuracy of measurements. The system gives the ability to reference objects is defined by users.

Quality control of large objects

Inspection of sheet metal parts and car bodies

Measuring of models and prototype

FARO ARM

The Faro Arm is a portable coordinate measuring machine (CMM) for easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis and more.

Shimadzu Servopulser

The Shimadzu Servopulser is a complete dynamic behavioral evaluation system with fully digital electro-hydraulic servo controller with which high speed loading and data acquisition.

This evaluates the dynamic characteristics (dynamic spring, damping factors, etc.) as a function of a maximum loading of 500Hz of vibration proof materials such as rubber and plastics.

This frame is suited to testing of small parts and formed specimens with a test force up to 200kN.

This can be used for toughness (fatigue) testing or static strength testing for safety evaluation.

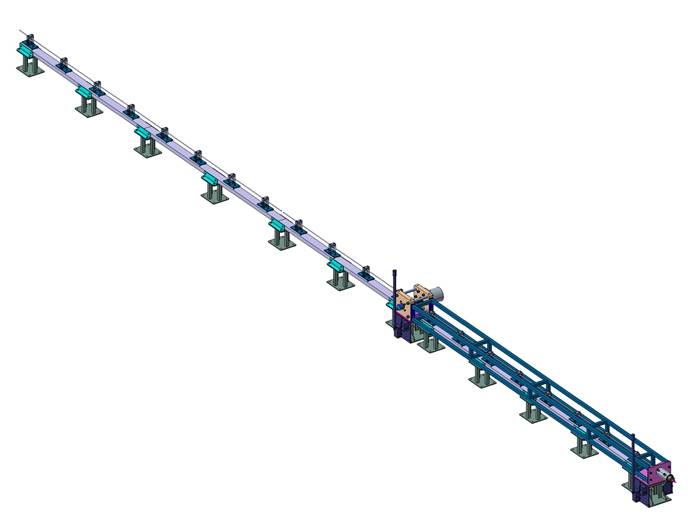

HOPKINSON BAR

Experimental set-up for high strain-rate test